Descrition:

1.We adopts 24forming stations with forged iron stands and 20T hydraulic decoiler and superonice sensor control to sychronize the speed between the roll forming machine and decoiler .The forming machine speed can reach up to 15m/min and stop-to-cut with cutting tolerance within 1.5mm

2 .We adopt gearbox drive to gurantee the machine performance stable and long-term running.

3.Corrugated Silo panels are widely used in the workd market .We have engaged in supplying the corrugated silo roll forming line to South American markets since 2008 .With stable performance and good forming product,we gained good reputations from our customers

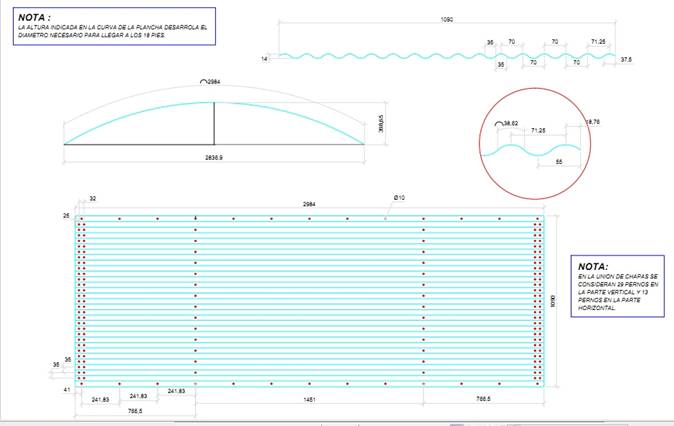

Drawing:

1 |

Material thickness |

mm |

0.8--3mm cold rolled steel |

2 |

Forming speed |

m/min |

12-15 |

3 |

Roll station |

/ |

24 |

4 |

Main power |

kw |

45 |

5 |

punching |

|

Hydraulic cutting |

6 |

Hydraulic power |

kw |

15kw |

7 |

Control system |

/ |

PLC panasonic/omron/simens/mitsubishi |

8 |

Drive |

/ |

Gearbox drive |

9 |

Decoiler |

|

10T/15T/20 hydraulic decoiler(coil car as option) |

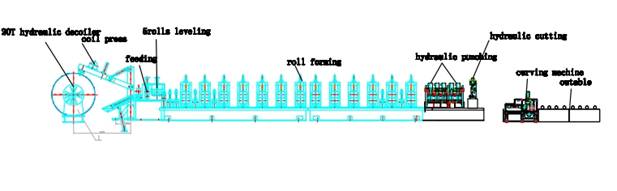

Flowchart:

|

←[Previous:] [Next:]→ |

High-speed Flying Shear Panel Forming Line

AG Panel Production Line

IBR 686 forming machine

Barrel corrugation machine

PBR Panel Production Line

Bemo Panel forming Machine

Standing Seam forming machine

Cassette Type Quick-changeable forming machine

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028