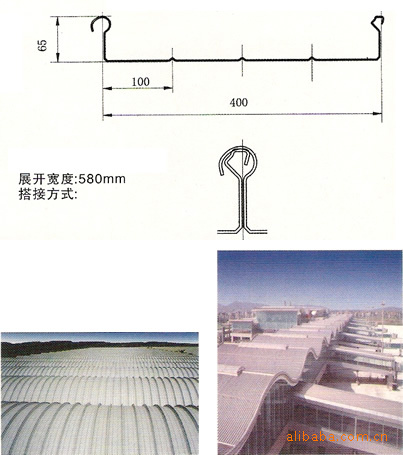

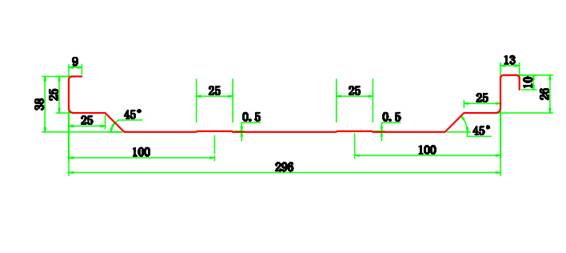

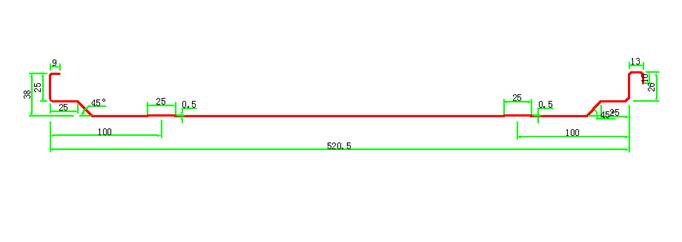

Drawing:

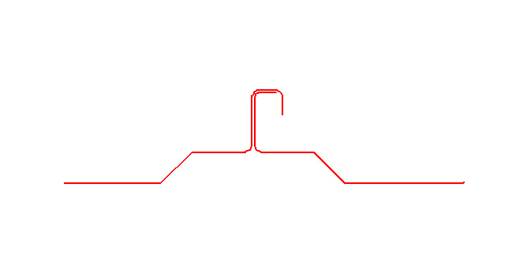

Overlapped drawing

Technical parameter

1 |

Material thickness |

mm |

0.4-0.9mm |

2 |

Forming speed |

m/min |

0-20 |

3 |

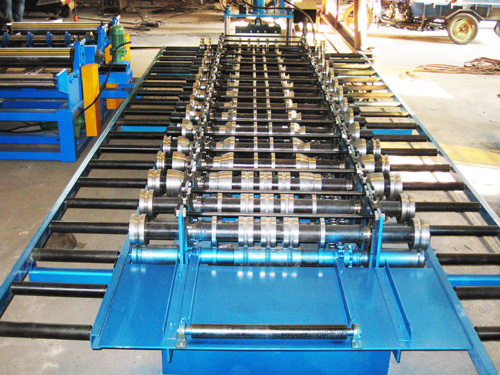

Roll station |

station |

12 |

4 |

Main power |

kw |

7.5 |

5 |

Hydraulic Power |

kw |

4 |

6 |

Control system |

/ |

PLC panasonic/omron/simens/mitsubishi |

7 |

Power supply |

|

380v,50Hz,3ph |

8 |

Drive |

/ |

Chain drive |

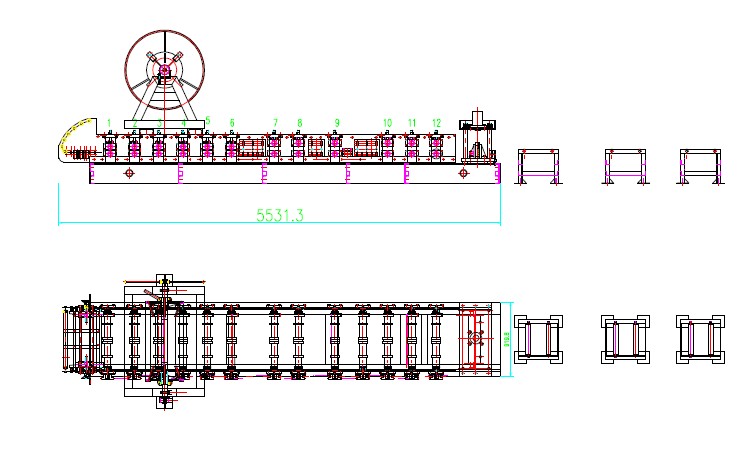

Flow chart

manual decoiler—feeding—roll forming—hydraulic cut-off—outables

components of the whole line

main roll forming machine |

1pc |

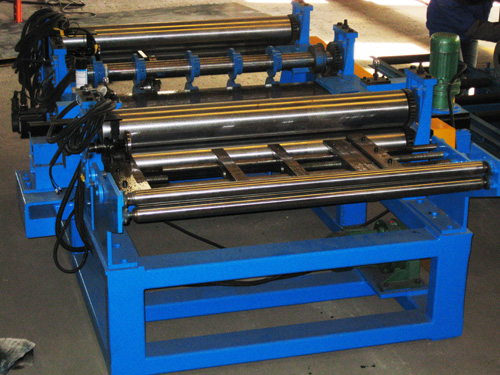

5T Manual decoiler |

1pc |

Hydraulic station |

1pc |

PLC cabinet |

1pc |

production output tables |

2 pcs |

Cutting blades |

2 sets |

Seamer machine |

1 pc |

Curving machine |

1 set |

|

[Next:]→ |

IBR 686 forming machine

Barrel corrugation machine

PBR Panel Production Line

Bemo Panel forming Machine

Cassette Type Quick-changeable forming machine

corrugated forming machine

Cranking machine

Double Layer forming machine

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028