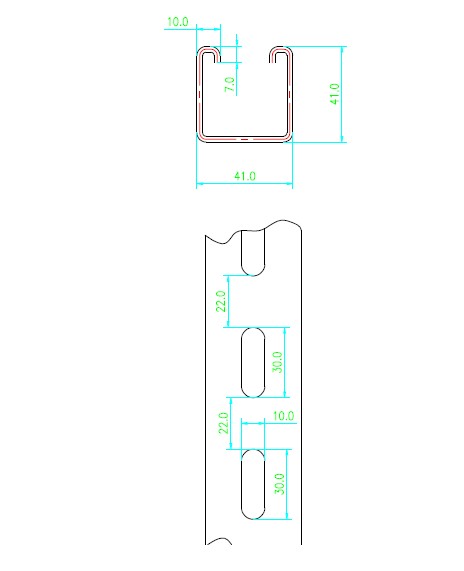

Drawing:

Process flow:

Motorized-decoiler-Powered leveling –Servo motor feeding-Hole punching- Forming-Hydraulic cutting-Output table

Main technical parameters :

※Finished products:41/41mm slotted Channels

※Raw material request:Q235 cold steel.

※Material thickness: 1.5mm--2.5mm

※Whole line working speed: >3-5m/min

Specifications:

NO. |

Name |

Quant. |

Remark |

1 |

Motoized decoiler |

1 |

3T |

2 |

Leveling machine |

1 |

5.5kw frequency change driving-motor,speed adjustable |

3 |

Speed control sensor |

1 |

It can make the punching and forming speed simutaneous |

4 |

NC300 servo motor Feeder |

1 |

NC300 Servo motor drive |

5 |

Punching press |

1 |

80tons Capacity |

6 |

Punching mould |

1set |

Cr12 |

7 |

Main forming |

1 |

16 forming stations |

8 |

Turkish head |

1 set |

It can make the product straight |

8 |

Hydraulic cutting |

1 |

Material GCr15,HCR58-62 |

9 |

Cutting blade |

1set |

Cr12 |

10 |

Run-out table |

1 |

Steel frame with Rollers |

11 |

Electric panel |

1 |

PLC control system,Panasonic/Omron |

12 |

Cooling&lubrication system |

1 |

|

|

[Next:]→ |

Non-Discontinuous PU panel line

Perforated Rolling Shutter Door Machine

PU FOAM SPRAYER MACHINE

PU panel line

Rolling Shutter Machine

Steel Door Panel Line

Door Frame Machine

European roller shutter forming machine

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028