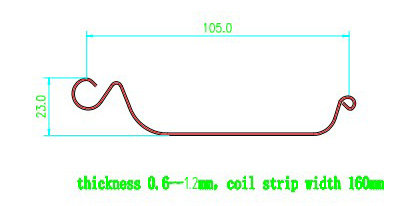

Profile show

Profile show

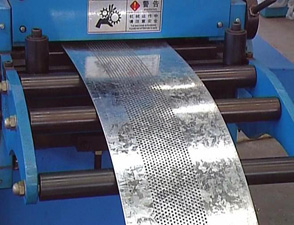

Equipment:

3T Decoiler, Roll forming machine, PLC cabinet, flying saw cutting, 63T punching press,holes punching mould,( 1 set),mechnical feeder,Output table(2),

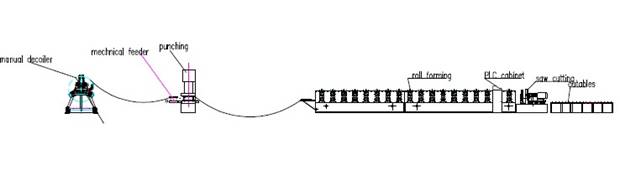

Flow chart:

Passive uncoiler --- Mechanical Feeder --- Holes Punching --- Forming --- Flying Saw Cutting --- Outables

Drawing:

Descrition:

1 |

Material thickness |

mm |

0.6-1.2mm Full hard,350Mpa |

2 |

Forming speed |

m/min |

12-15 |

3 |

Roll station |

/ |

14 |

4 |

Main power |

kw |

7.5 |

5 |

Cutting power |

kw |

5.5 |

6 |

Control system |

/ |

PLC panasonic/omron/simens/mitsubishi |

7 |

Holes punching |

|

80T punching press made in China |

8 |

feeder |

|

Mechnical feeder |

9 |

Drive |

/ |

Chain drive |

10 |

Decoiler |

3 |

3T manual decoiler |

|

[Next:]→ |

European roller shutter forming machine

Non-Discontinuous PU panel line

Door Frame Machine

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028