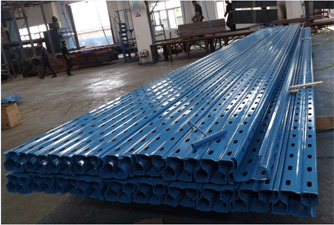

Profile show:

Profile show:

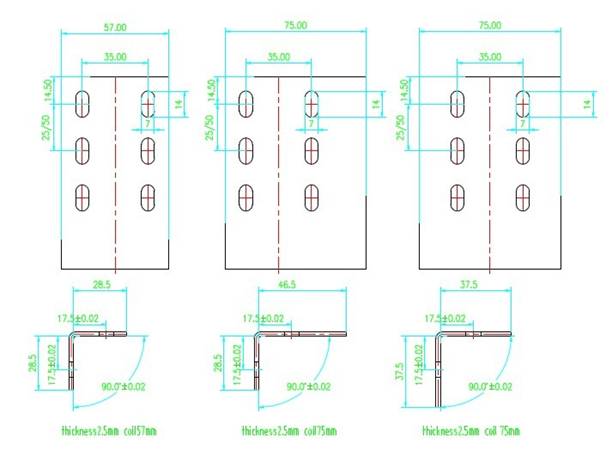

L profiles Drawing:

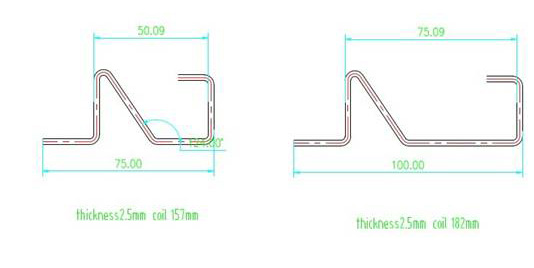

Z Beam profiles:

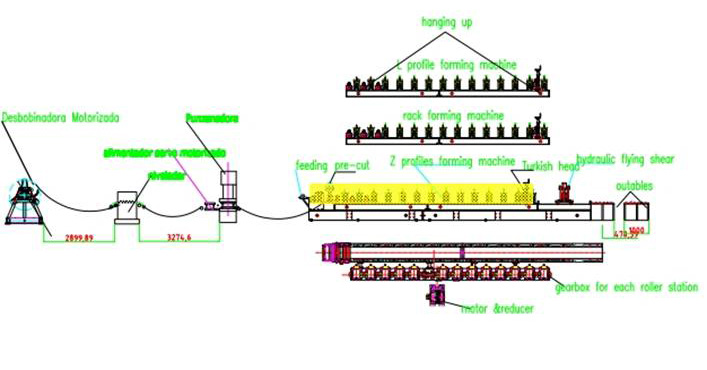

Flowchart:

NO. |

Name |

Quant. |

Remark |

1 |

Double head motorized decoiler |

1 |

Max 3T(1.5T for each head) |

2 |

Leveling machine |

1 |

5.5kw frequency change driving-motor,speed adjustable |

3 |

Support frame(loop sensor) |

2 |

Roller type |

4 |

NC300 servo motor Feeder |

1 |

1.5kw Yaskawa Servo motor drive |

5 |

Punching press |

1 |

125tons Capacity made in china |

6 |

Punching mould( one for rack profiles,one for L profiles) |

2sets |

Cr12 |

7 |

Main forming |

1set |

Cast iron stands

|

8 |

Hydraulic flying shear |

1 set |

Hydraulic flying shear for rack profile and L profile,pre-cut for Z profiles |

9 |

Cutting blade |

4sets |

Material Cr12.HCR58-62 |

10 |

Run-out table |

2pcs |

Steel frame with Rollers |

11 |

Electric panel |

2sets( 1set for mail machine,1 set for servo-feeder system) |

PLC control system,Panasonic or Omron,Omron encoder,Yaskawa inverter |

|

←[Previous:] [Next:]→ |

Upright Roll Forming Machine

Cable Tray Forming Machine

Box Panel Forming Machine

Step Beam Forming Machine

Decoiler,leveller and servo-feeder

C Beam Forming Machine

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028