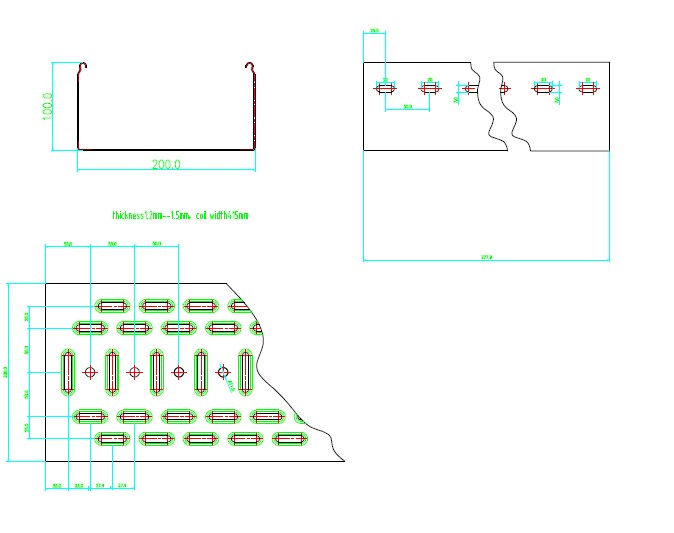

Profile show:

Profile show:

Drawing:

Main technical parameters:

※Finished products:100x200 Cable tray with holes punching

※Raw material request:G300Mpa cold steel or galvanized steel

※Material thickness:1.0mm-1.5mm

※Whole line working speed: >3--5m/min

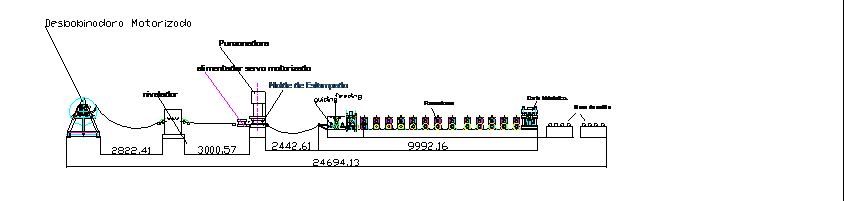

※Process flow:

Motorized de-coiler-Powered leveling –Servo feeder-Holes punching- Forming-Hydraulic cutting-Output table

NO. |

Name |

Quant |

Remark |

1 |

Motorized decoiler |

1 |

Max 5T |

2 |

Leveling machine |

1 |

5.5kw frequency change driving-motor,speed adjustable |

3 |

NC300 servo motor Feeder |

1 |

1.5kw Yaskawa Servo motor drive |

5 |

Punching press |

1 |

160 tons Capacity made in Yangli Group in china |

6 |

Punching mould |

1set |

Cr12 Mov |

7 |

Main forming |

1set |

Torri stands |

8 |

Hydraulic cutting |

1 set |

|

9 |

Cutting blade |

1set |

Material Cr12,HCR58-62 |

10 |

Run-out table |

2pcs |

Steel frame with Rollers |

11 |

Electric panel |

1set |

PLC control system,Panasonic/Omron/Siemens |

|

←[Previous:] [Next:]→ |

Box Panel Forming Machine

C Beam Forming Machine

Decoiler,leveller and servo-feeder

Heavy-Duty Upright .L profile,Beam Forming Machine

Step Beam Forming Machine

Upright Roll Forming Machine

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028

Add:2-627,Xiangjiang North Road,New District,Wuxi City Post code:214028